Laser cutting has established itself as a key element in contemporary manufacturing, providing unmatched accuracy, rapidity, and adaptability across various sectors. Its advancements have influenced fields like aerospace, automotive, healthcare, and microelectronics, continuously pushing the boundaries of precision engineering. Currently, advancements in automation, materials technology, artificial intelligence, and sustainability are improving the efficiency of laser cutting while also influencing the future of industrial manufacturing.

This article delves into the significant trends propelling the progress of laser cutting evolution, the emerging technologies that are establishing new benchmarks, and the transformative impact these innovations have on precision engineering.

The Evolution of Laser Cutting Technology

Since its commercial debut in the 1960s, laser cutting technology has significantly evolved. Originally, it was restricted to cutting metals and other tough materials, utilising CO₂ lasers. While this represented a groundbreaking advancement, early systems faced limitations in terms of speed, energy efficiency, and maintenance requirements.

However, through the years, advancements in laser generation, optics for focusing, and computerised control systems have transformed laser cutting into one of the most versatile and effective manufacturing techniques available today.

Understanding the laser cutting evolution is crucial for industries seeking to enhance efficiency and innovation.

Plasma cutting technology utilises a high-velocity jet of ionised gas to precisely cut through electrically conductive materials such as steel, aluminium, and copper with speed and accuracy.

From CO₂ to Fiber Lasers: A Technological Leap

The transition from CO₂ lasers to fibre lasers represents a major breakthrough in the development of laser cutting technology. Fibre lasers, utilising optical fibres infused with rare-earth elements such as ytterbium, offer enhanced energy efficiency, increased cutting speed, and reduced operating expenses.

Advantages of Fibre Laser Technology

- Enhanced Efficiency: Fibre lasers are able to transform electrical energy into light with greater effectiveness, leading to lower energy use and decreased operational expenses.

- Superior Beam Quality: The more concentrated beam enables more precise cutting and improved tolerance levels.

- Lower Maintenance Needs: In contrast to CO₂ lasers that necessitate frequent mirror adjustments and gas replenishment, fibre lasers provide a longer service life with very little upkeep required.

- Versatile Material Capability: These lasers can handle reflective materials like copper, aluminium, and brass, which presented difficulties for CO₂ lasers in the past.

This transition has empowered manufacturers to achieve unprecedented precision, reliability, and sustainability in production environments.

Emerging Trends Shaping the Future of Laser Cutting

With the growing need for enhanced precision and quicker production times in various industries, a number of significant trends are surfacing in laser cutting technology. These developments are reshaping the concept of precision engineering within contemporary manufacturing practices.

1. Integration of Artificial Intelligence and Automation

Artificial Intelligence is transforming the field of laser cutting by allowing machines to optimise themselves, adjust to different materials instantly, and forecast maintenance requirements. When paired with automation, AI-enhanced laser cutters can operate flawlessly 24/7.

Intelligent Manufacturing and Anticipatory Maintenance

- Automated Process Modifications: AI systems assess laser settings while cutting, dynamically modifying focus, speed, and power to ensure uniform results.

- Minimising Errors: Continuous monitoring identifies issues like beam misalignment or temperature fluctuations, reducing the chance of defects.

- Anticipatory Maintenance: Sensors gather data from the machines to foresee parts wear, helping to avoid expensive downtime.

Collaborative Robots (Cobots) and Laser Systems

Collaborative robots are now being paired with laser cutting systems to automate repetitive tasks such as part loading, sorting, and finishing. This combination allows for increased productivity, improved worker safety, and enhanced workflow efficiency.

2. Advancements in Material Processing Capabilities

The variety of materials available has grown significantly in recent years. Laser cutting technology has evolved beyond just conventional metals to include ceramics, composites, polymers, and even biological materials used in medical engineering.

Laser Micro-Machining and Precision Components

Micro laser cutting enables engineers to fabricate parts with dimensions smaller than a human hair. This technology is especially important in fields such as microelectronics and biomedical devices, where pinpoint accuracy is crucial.

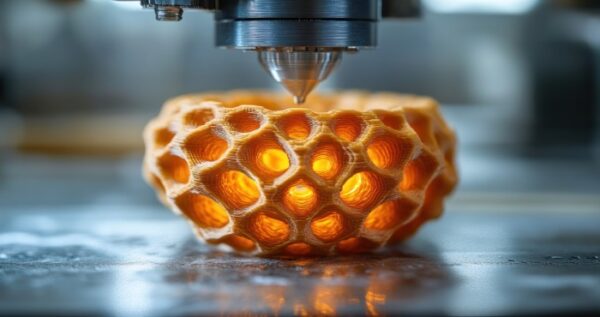

4D and Hybrid Material Applications

In addition to 3D technology, scientists are investigating 4D laser cutting, which utilises shape-memory materials that change their shape in response to certain conditions. This advancement presents exciting possibilities for aerospace and robotics, allowing for structures that can adapt to changes in their environment.

Digital Transformation and Connectivity

With the adoption of Industry 4.0 concepts in manufacturing, laser cutting systems are transforming into smart, networked tools that can interact throughout the entire production process.

IoT and Data-Driven Laser Cutting

Integrating the Internet of Things (IoT) enables laser cutting machines to send performance information, allowing manufacturers to enhance their production processes in real-time.

1. Data Analytics and Cloud Integration

- Distance Oversight: Engineers have the ability to monitor laser functionality, energy consumption, and production levels from any location.

- Efficiency Enhancement: Advanced data analysis reveals inefficiencies and provides recommendations to minimise waste and boost production.

- Cloud-Enabled Teamwork: Teams in different locations can concurrently access design documents and cutting specifications, leading to quicker prototyping.

2. Digital Twin Technology

A digital twin is a virtual model of a laser cutting system that mimics actual operations. This technology aids manufacturers in anticipating performance, enhancing maintenance practices, and minimising equipment wear proactively, preventing potential problems before they arise.

Sustainability and Green Manufacturing Initiatives

Sustainability has become a crucial focus in precision engineering. The process of laser cutting, recognised for its efficient use of materials, is being refined to meet worldwide eco-friendly manufacturing benchmarks.

Energy Efficiency and Waste Reduction

Contemporary fibre laser systems use considerably less energy compared to their predecessors, generating reduced heat and waste in the process.

Eco-Friendly Innovations in Laser Cutting

- Closed-Loop Cooling Systems: Minimise water usage and energy expenditure.

- Material Recycling: Enhanced filtration systems recover and repurpose metal dust.

- Optimised Nesting Software: Increases efficiency in material use, reducing waste.

Laser Cutting and Circular Economy

Laser cutting promotes circular manufacturing by increasing the longevity of materials and reducing waste, allowing for the reuse or repurposing of every component and byproduct. This environmentally-focused strategy enhances both ecological well-being and sustainable profits over time.

Precision Engineering Applications Redefined

The advancements in laser cutting extend beyond merely the machinery; they encompass its diverse applications across various sectors, revolutionising the standards of precision in engineering.

Innovations in Aerospace and Automotive Sectors

These fields require durable and lightweight materials capable of enduring harsh conditions. Laser cutting offers the precision necessary for the fabrication of complex parts utilised in engines, vehicle frames, and electrical systems.

Laser Cutting in Electric Vehicle Production

The surge in electric vehicle popularity is driving the necessity for laser-fabricated battery elements, connectors, and casings. The accuracy of laser cutting is essential in ensuring the functionality and safety of these vital components.

Use of Laser Cutting in Composite Materials

Laser cutting allows engineers to manipulate intricate composite layers without risk of delamination, which is vital for aerospace structures that demand both strength and minimal weight.

Medical and Microengineering Precision

Laser technology plays an ever-growing role in the fields of healthcare and biotechnology. The production of medical devices, such as stents, catheters, and microfluidic chips, relies significantly on the accuracy of laser manufacturing.

Biocompatible and Micro-Scale Applications

- Non-Thermal Cutting: Minimises thermal harm to sensitive materials such as bio-polymers.

- Precision at the Micron Scale: Crucial for the fabrication of implants and surgical tools.

- Cleanroom Compatibility: Guarantees hygienic manufacturing conditions in facilities producing medical-grade products.

4D Biofabrication Potential

New studies are investigating the application of lasers for cutting and moulding biocompatible scaffolds, which can change in shape or functionality. This could lead to the development of dynamic implants that adjust within the human body.

Future Outlook: The Next Frontier in Laser Cutting

With the ongoing advancements in technology, the future of laser cutting looks set to embrace enhanced integration, smarter capabilities, and innovative solutions.

Quantum and Ultrafast Laser Technology

Ultrafast lasers, including femtosecond lasers, function in the realm of quadrillionths of a second. Their exceptional precision enables the processing of materials without causing heat-affected zones. This advancement is set to revolutionise industries such as microelectronics, nanotechnology, and photonics manufacturing.

Engineering at the Nanoscale

Femtosecond lasers allow engineers to alter the characteristics of materials on an atomic scale, opening doors to quantum-level components essential for advanced computing and optical technologies.

Redefining Miniaturisation

The capacity to develop intricate, extremely tiny components will transform the possibilities in consumer electronics, semiconductor innovation, and medical testing.

Challenges and Opportunities Ahead

1. Challenges in Adopting Advanced Laser Cutting Technologies

Even with swift advancements, the uptake of next-generation laser cutting technologies encounters significant obstacles. The steep initial expense associated with cutting-edge fibre and ultrafast lasers often discourages smaller and medium-sized enterprises. These advanced systems require a considerable upfront financial commitment, which can put pressure on budgets and postpone the adoption of new technologies.

A further difficulty is the lack of skilled operators. Effectively managing AI-integrated and IoT-enabled systems demands specialised training. Without proper education, even the most sophisticated machines may fall short of optimal performance, hindering productivity and accuracy. Moreover, as manufacturing environments become interconnected, the risks to data security increase, emphasising the importance of robust cybersecurity measures in the industry.

2. Collaborating to Overcome Barriers

Joint initiatives among businesses, educational institutions, and government agencies are critical to overcoming these challenges. Partnerships between industry and academia are creating tailored training programs that equip operators with the necessary skills to proficiently manage advanced laser technologies.

Additionally, government incentives and innovation grants are aiding small enterprises in the transition to precision laser solutions. These programs not only enhance access to state-of-the-art tools but also cultivate a skilled workforce poised to foster future advancements in manufacturing.

3. The Importance of Standardisation and Global Integration

For the global laser cutting sector to flourish, interoperability is essential, making standardisation a top priority. Establishing universal standards for laser safety, software integration, and energy efficiency can streamline production processes and ensure consistent quality across the globe.

As various regions begin to align their regulations and standards, the integration of precision engineering on a global scale will accelerate. This alignment will facilitate international trade in laser-cut components, lower market entry barriers, and promote cross-border collaborative innovation.

A Future Defined by Light and Intelligence

The advancements in laser cutting symbolise the larger shift occurring within precision engineering, characterised by intelligence, sustainability, and connectivity. From automated systems enhanced by artificial intelligence to unprecedented levels of accuracy at the quantum scale, each breakthrough unlocks fresh avenues for efficiency and innovation. Explore advanced laser cutting technologies at ACRA Machinery.

Looking forward, laser cutting will play a crucial role in fostering intelligent manufacturing environments, where machines possess cognitive capabilities, materials modify themselves, and engineering precision achieves feats previously deemed unachievable. The merging of digital intelligence with laser technology represents a transformation that is fundamentally redefining the future of precision engineering.