Metal cutting methods are at the heart of modern manufacturing, shaping raw materials into precise, functional components that drive industries across Australia. For businesses working with sheet metal machinery, understanding the full spectrum of cutting techniques is essential not only for productivity but also for extending the lifespan of valuable equipment. From traditional mechanical approaches like shearing and punching to high-tech solutions such as laser and water jet cutting, each method offers unique advantages depending on material type, thickness, and project requirements. Choosing the right technique can save time, reduce waste, and ensure cleaner, more accurate cuts. Equally important is the proper maintenance of sheet metal machinery, which keeps operations running smoothly and prevents costly downtime. Whether you’re fabricating intricate designs or handling heavy steel plates, a thorough grasp of metal cutting methods is key to achieving efficiency, precision, and long-term reliability in any workshop.

Mechanical Cutting Methods

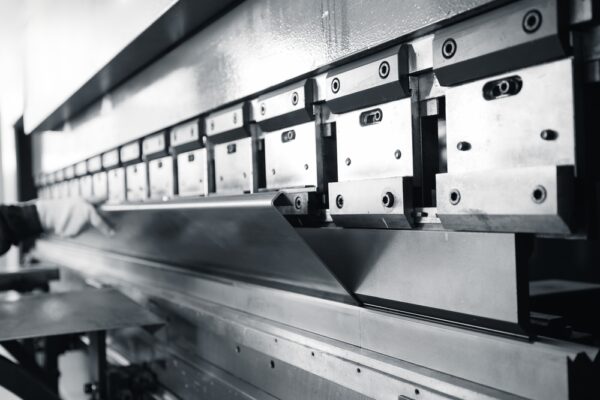

Mechanical cutting methods form the foundation of sheet metal fabrication, relying on physical force to separate or shape metal. For workshops and manufacturers in Melbourne and across Australia, these techniques are often the most cost-effective and widely used, particularly for routine cutting tasks.

Shearing is one of the simplest and most efficient mechanical methods. It involves using straight blades to slice through sheet metal, producing clean edges with minimal material waste. Shearing is ideal for cutting large sheets quickly, though regular blade inspections are crucial to maintain accuracy and prevent uneven cuts.

Sawing offers a versatile alternative for cutting metals of varying thicknesses. Band saws and circular saws are commonly used, with CNC-controlled saws providing higher precision for complex shapes. Saw blades must be regularly checked and replaced to avoid wear, which can compromise both the quality of cuts and the performance of the machinery.

Punching and stamping are widely used in high-volume sheet metal operations. Punching employs a die and press to create holes or specific shapes in the metal, while stamping presses can form intricate patterns or embossing. CNC punching machines allow for consistent, repeatable results, but maintaining tooling is essential to prevent breakages and ensure worker safety.

For any sheet metal workshop, understanding these mechanical cutting methods is crucial. Not only do they offer reliable and cost-effective solutions for everyday cutting needs, but when paired with diligent maintenance, they also prolong the life of the sheet metal machinery, reduce downtime, and improve overall production efficiency.

Thermal Cutting Methods

Thermal cutting methods use heat to cut through metal, offering precision and speed that mechanical techniques sometimes cannot match. For sheet metal workshops in across the country, these methods are particularly useful when working with thicker metals or complex designs, as they can deliver clean edges with minimal physical force.

Oxy-fuel cutting is one of the oldest and most reliable thermal methods. It involves a flame that heats the metal to its ignition temperature, while a stream of oxygen burns through the material. Oxy-fuel cutting is ideal for heavy steel plates and structural components, providing deep, accurate cuts. Regular maintenance of torches, regulators, and gas supply lines is essential to ensure safety and consistent performance.

Plasma cutting has become a popular choice for medium-thickness metals, especially in high-speed or CNC-controlled operations. By generating a jet of ionised gas at extremely high temperatures, plasma cutters can slice through steel, aluminium, and other conductive metals with precision. Maintaining electrodes, nozzles, and machine calibration is critical to avoid uneven cuts or reduced efficiency.

Laser cutting represents the pinnacle of precision in thermal cutting. Using focused light beams, lasers can create intricate shapes and designs with minimal edge finishing required. This method is particularly beneficial for high-volume production or delicate, detailed work. Regular cleaning of lenses and mirrors, along with proper alignment, ensures the machinery continues to operate at peak performance.

For sheet metal operations, selecting the right thermal cutting method depends on material type, thickness, and production requirements. When combined with routine maintenance, thermal cutting techniques not only enhance productivity but also prolong the lifespan of sheet metal machinery, reduce waste, and maintain consistent quality across all projects.

Advanced Cutting Methods

For workshops seeking precision and versatility beyond traditional mechanical and thermal techniques, advanced cutting methods offer innovative solutions. These methods are particularly useful when handling heat-sensitive metals or intricate designs that demand minimal distortion.

Water jet cutting is a standout example, using a high-pressure stream of water, often mixed with abrasive materials, to cut through metal. Unlike thermal methods, water jet cutting generates no heat-affected zone, preserving the structural integrity of sensitive alloys and producing smooth, accurate edges. This makes it an excellent choice for metals that could warp or discolour under high temperatures. Regular maintenance of pumps, nozzles, and abrasive feed systems ensures consistent cutting quality.

Emerging technologies, including hybrid cutting methods that combine mechanical and thermal approaches or utilise advanced CNC automation, are gradually transforming metal fabrication. These innovations allow for increased flexibility, faster production times, and higher precision, while also reducing material waste.

For sheet metal machinery operators in Australia, understanding advanced cutting methods not only broadens the range of projects they can undertake but also highlights the importance of keeping machinery well-maintained. Proper care ensures that these sophisticated systems deliver optimal performance and long-term reliability.

Factors Affecting Choice of Cutting Method

Selecting the right metal cutting method involves more than just choosing between mechanical, thermal, or advanced techniques. For sheet metal machinery operators, owners, and businesses across the country, several key factors influence this decision.

Material type and thickness are primary considerations. Harder or thicker metals may require thermal or water jet cutting, while thinner sheets can often be handled efficiently with mechanical methods. Precision requirements also play a role; intricate designs or components with tight tolerances often benefit from laser or water jet cutting.

Production volume and speed are equally important. High-volume operations may rely on CNC punching or plasma cutting to maintain consistency and efficiency, while smaller, bespoke projects might use shearing or manual laser cutting.

Finally, equipment cost and maintenance requirements can determine the most practical option. Choosing a method that balances productivity, precision, and machinery longevity ensures smoother operations, lower downtime, and better long-term value for any workshop.

Maintenance Tips for Cutting Machinery

Regular machinery maintenance is essential to keep sheet metal machinery operating efficiently and safely. For workshops in Melbourne, consistent care not only prolongs equipment lifespan but also ensures precision and reduces downtime.

Routine inspections should include checking blades, punches, and cutting tools for wear or damage. Dull or worn components can compromise cut quality and place unnecessary strain on machinery. Calibration of CNC systems, lasers, and plasma cutters ensures accuracy, while lubrication of moving parts minimises friction and mechanical wear.

Keeping machinery and workspaces clean is equally important. Dust, metal shavings, and debris can interfere with cutting performance or damage sensitive components. Scheduling preventative maintenance and adhering to manufacturer guidelines helps identify potential issues early, avoiding costly repairs or production delays.

For Melbourne workshops handling sheet metal, combining regular maintenance with proper operation practices guarantees that cutting machinery delivers consistent, high-quality results, project after project.

Do You Need Sheet Metal Machinery in Melbourne?

Understanding the range of metal cutting methods is essential for any sheet metal workshop in Melbourne. When you are looking for sheet metal machinery expertise, look no further than ACRA Machinery. We are backed by 42 years of industry experience and are ready to help with sheet metal machinery sales, repair and maintenance.

Get in touch with ACRA by calling 03 9794 6675 or fill out our online contact form and we will get back to you.

Frequently Asked Questions

How do I choose the right metal cutting method?

The choice depends on material type, thickness, precision requirements, and production volume. Mechanical methods suit thinner sheets, while thermal or water jet cutting is better for thicker or heat-sensitive metals.

What is the difference between mechanical and thermal cutting?

Mechanical cutting uses force to shear, saw, or punch metal, whereas thermal cutting melts or burns through the material using heat, such as in plasma, laser, or oxy-fuel cutting.

How often should sheet metal machinery be maintained?

Routine inspections, blade and tool replacements, calibration, and lubrication should be carried out regularly to ensure accuracy, safety, and longevity.

Can water jet cutting replace laser cutting?

Water jet cutting is ideal for heat-sensitive metals and thicker materials, while laser cutting offers greater precision for intricate designs.

What safety measures are essential for metal cutting?

Use protective gear, maintain clean workspaces, ensure correct tool setup, and adhere to machinery maintenance schedules to prevent accidents.

Can regular maintenance improve the lifespan of sheet metal machinery?

Yes, routine maintenance such as blade inspections, lubrication, and calibration helps prevent wear and breakdowns, ensuring cutting machinery remains precise, efficient, and long-lasting.