Automated sheet metal fabrication is transforming the way Australian workshops approach precision metalworking. Gone are the days when sheet metal machinery operators relied solely on manual presses, hammers, and hand tools to shape and form components. Today, advanced machinery equipped with CNC technology, robotic arms, and laser cutting systems is enabling manufacturers across Melbourne and beyond to produce high-quality parts faster, more consistently, and with less waste. For workshops facing increasing demand, tight deadlines, and the need for flawless accuracy, automation isn’t just a convenience, it’s a competitive necessity. Beyond speed and efficiency, automated systems offer enhanced repeatability, minimise errors, and ensure compliance with industry standards. In a market where precision matters, investing in modern fabrication technology allows businesses to stay ahead of the curve, expand capabilities, and meet client expectations without compromise.

Understanding Automated Sheet Metal Fabrication

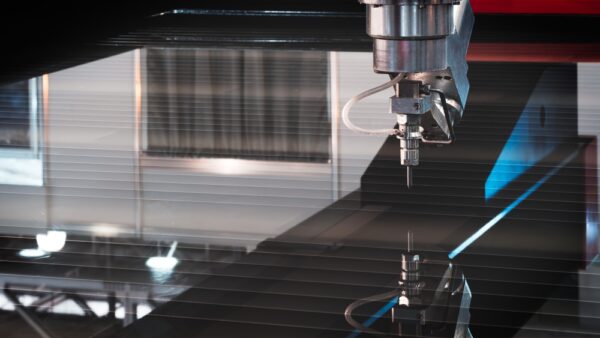

Automated sheet metal fabrication refers to the use of computer-controlled machinery and robotic systems to cut, bend, punch, and assemble sheet metal components with minimal human intervention. Unlike traditional manual methods, automation integrates CNC technology, precision laser cutting, and robotic arms to deliver consistent, high-quality results. This modern approach reduces the risk of errors, increases repeatability, and streamlines production processes for manufacturers across Australia.

The core technologies involved in automated fabrication include CNC press brakes, laser cutters, and turret punches. These machines are often paired with advanced software, such as CAD and CAM systems, which allow designers to create complex parts digitally before sending precise instructions to the machinery. In addition to hardware and software, automated workflows often incorporate sensors, conveyors, and automated material handling systems to further enhance efficiency and reduce operator fatigue.

Workshops adopting automation can produce intricate architectural components, automotive parts, and industrial machinery with remarkable accuracy. Over time, these systems not only improve output but also reduce material waste and maintenance costs. For Australian manufacturers, investing in automated sheet metal fabrication provides a competitive edge, enabling businesses to meet tighter deadlines and maintain consistent quality across all production runs.

Key Benefits of Automation in Sheet Metal Fabrication

Investing in automated sheet metal fabrication brings significant advantages to modern workshops, particularly for manufacturers in Melbourne and across Australia. These systems are designed to enhance precision, improve productivity, and reduce operational costs, all while maintaining consistent quality. Automation allows workshops to achieve results that would be challenging or impossible with traditional manual methods.

Enhanced Precision and Accuracy

One of the most important benefits is improved precision. CNC-controlled machines and laser cutters ensure every cut, bend, or punch aligns perfectly with design specifications. This reduces the risk of human error and minimises material waste, which is particularly critical in industries like aerospace, automotive, and architectural metalwork. Precision metalworking also supports compliance with Australian standards, helping businesses maintain quality assurance and client trust.

Increased Productivity and Efficiency

Automated machinery significantly boosts production speed by operating continuously and performing repetitive tasks more efficiently than manual methods. Modern systems can handle complex shapes, high-volume production runs, and intricate components with minimal intervention, allowing operators to focus on other aspects of manufacturing.

Cost Savings and Return on Investment

Although the upfront investment can be substantial, automation reduces long-term costs. Less material waste, fewer errors, and lower labour requirements contribute to a strong return on investment. For Australian workshops, the combination of improved efficiency, repeatable quality, and reduced downtime makes automated sheet metal fabrication a smart, strategic choice for sustainable growth and competitiveness.

Technologies Driving Automated Fabrication

Modern automated sheet metal fabrication relies on a combination of advanced machinery, software, and robotic systems to deliver high-quality, precise results. These technologies enable Australian workshops to produce complex components efficiently while maintaining strict tolerances and consistency. Understanding the key technologies involved can help businesses make informed decisions when upgrading or expanding their facilities.

CNC Machines

CNC, or Computer Numerical Control, machines form the backbone of automated metalworking. CNC press brakes, laser cutters, and turret punches are programmed with precise instructions to execute accurate cuts, bends, and holes. By integrating CAD and CAM software, operators can design components digitally and transfer them directly to the machinery, reducing errors and improving workflow efficiency.

Robotics and Automation

Robotic arms and automated material handling systems play a critical role in enhancing productivity. These systems can load, position, and manipulate sheet metal with consistent precision, reducing the reliance on manual labour and minimising the risk of damage or injury. Automated conveyors and feeders further streamline the production line, ensuring continuous operation.

Advanced Software Integration

Software solutions, including CAD/CAM, simulation tools, and monitoring systems, allow workshops to optimise processes and manage production data. Predictive maintenance and real-time diagnostics help identify potential issues before they disrupt operations, ensuring machinery runs at peak performance.

Applications Across Industries

Automated sheet metal fabrication has transformed manufacturing across a wide range of industries in Australia. Its precision, speed, and repeatability make it ideal for producing complex components that require tight tolerances and consistent quality. Australian workshops, particularly in Melbourne and Victoria’s industrial hubs, are leveraging these technologies to meet increasing demand for high-quality, reliable products.

In the automotive sector, automated systems are used to fabricate body panels, chassis components, and custom parts with minimal errors. The ability to produce consistent components at scale has helped local manufacturers remain competitive in both domestic and international markets.

The aerospace industry benefits from automation due to the strict precision requirements for aircraft components. CNC machines, laser cutters, and robotic systems enable workshops to create intricate parts that meet rigorous safety and quality standards.

Other sectors such as construction, industrial machinery, and architectural metalwork also rely heavily on automated fabrication. From cladding panels to industrial enclosures and specialised machinery parts, these technologies allow manufacturers to deliver complex designs efficiently.

Challenges and Considerations

While automated sheet metal fabrication offers numerous benefits, it is not without challenges. Australian workshops considering investment in these technologies must carefully evaluate costs, workforce skills, and integration requirements before committing to new machinery. Understanding these considerations helps ensure a smooth transition and maximises the return on investment.

High Initial Investment

One of the primary challenges is the upfront cost of purchasing advanced machinery. CNC machines, laser cutters, and robotic systems require significant capital, which may be a barrier for smaller workshops. However, this investment often pays off in the long term through reduced labour costs, lower material waste, and higher productivity.

Workforce Training

Automation demands a skilled workforce capable of operating, programming, and maintaining sophisticated equipment. Australian manufacturers must provide comprehensive training to ensure staff can use machines effectively and safely, avoiding downtime and errors.

Integration and Maintenance

Integrating automated systems into existing production lines can be complex. Workshops need to consider workflow optimisation, software compatibility, and ongoing preventative maintenance. Regular servicing and calibration are essential to maintain precision and extend machinery lifespan.

Future Trends in Automated Sheet Metal Fabrication

The future of automated sheet metal fabrication is being shaped by advancements in technology, connectivity, and sustainability. Australian workshops are increasingly adopting smart manufacturing practices, integrating artificial intelligence, IoT-enabled machinery, and data analytics to improve production efficiency and precision. These innovations allow manufacturers to monitor machine performance in real time, predict maintenance needs, and reduce unplanned downtime.

Choosing the Right Automated Solutions for Your Workshop

Selecting the right automated sheet metal fabrication equipment is a critical decision for any Australian workshop. The ideal solution balances production requirements, precision, and budget while supporting long-term business growth. Understanding your specific needs ensures that investments in CNC machines, laser cutters, or robotic systems deliver maximum efficiency and return on investment.

Key Considerations

Workshops should evaluate factors such as production volume, material types, and the complexity of parts being manufactured. Compatibility with existing software, ease of integration into current workflows, and ongoing maintenance requirements are also crucial considerations.

Partnering with a local supplier in Melbourne or Victoria can provide significant advantages, including personalised support, faster access to spare parts, and on-site service. A trusted supplier can guide workshops through machinery selection, installation, and training, ensuring that the automated solutions chosen enhance precision, productivity, and operational efficiency from day one.

Do You Need Sheet Metal Machinery?

If you are looking for sheet metal machinery and are ready to upgrade, look no further than ACRA Machinery. Backed by over 40 years of industry experience, we are here to help with all of your sheet metal needs, including sales, repair, and maintenance.

Get in touch with us by calling 03 9794 6675 or fill out our online contact form and we will get back to you.

FAQ: Automated Sheet Metal Fabrication

What is automated sheet metal fabrication?

Automated sheet metal fabrication is the process of using computer-controlled machinery, such as CNC machines and robotic systems, to cut, bend, punch, and assemble sheet metal components with minimal human intervention. This method improves accuracy, efficiency, and consistency across production runs.

How does automation improve precision and efficiency?

Automation ensures components are manufactured to exact specifications by reducing human error. CNC programming, laser cutting, and robotic handling allow workshops to produce complex designs faster, with less material waste and consistent quality.

Which industries benefit most from automated sheet metal machinery?

Industries such as automotive, aerospace, construction, industrial machinery, and architectural fabrication see the greatest advantages. Any sector requiring high-precision components and repeatable results can benefit from automation.

How often should automated machines be serviced or calibrated?

Regular servicing and calibration are essential to maintain accuracy and extend equipment lifespan. Many workshops schedule full calibration annually, with basic checks more frequently, depending on machine usage and production demands.