Sheet metal bending techniques are at the heart of modern fabrication; shaping flat sheets of metal into functional and precise components used across countless industries. Whether in automotive, aerospace, construction, or architectural design, bending processes determine the strength, durability, and accuracy of the final product. For Australian workshops, mastering these techniques is essential to staying competitive in a fast-paced market. Advances in sheet metal machinery, such as CNC press brakes and automated systems, have transformed traditional methods, delivering higher precision and efficiency while reducing waste. From simple bends to complex curves and channels, today’s technology allows fabricators to achieve results that were once difficult to produce with consistency. This month we explore the fundamentals of bending, the different methods available, and the role of modern automation in shaping the future of Australian metalworking.

Fundamentals of Sheet Metal Bending

At its core, sheet metal bending is the process of applying force to a flat sheet so that it takes on a specific angle, curve, or shape without breaking or damaging the material. The success of any bend depends on the balance between tensile strength, compressive forces, and the ductility of the chosen alloy. These physical properties determine how the sheet behaves when manipulated under pressure.

Bending is influenced by several factors, including the thickness of the sheet, the type of metal, and the tooling used in the operation. For instance, aluminium requires different handling compared to steel, and each material has its own spring-back characteristics that must be compensated for during production.

Understanding the fundamentals also involves recognising common terms such as bend allowance, bend radius, and neutral axis. These calculations ensure precision, allowing workshops to consistently deliver components that fit seamlessly into larger assemblies across industries like automotive, construction, and electronics.

By grasping these essential principles, fabricators can choose the right method, minimise material waste, and optimise production quality, ensuring their processes remain efficient and cost-effective in an increasingly competitive manufacturing environment.

Common Sheet Metal Bending Techniques

Sheet metal bending can be carried out using a variety of techniques, each suited to different production requirements and levels of precision. The most widely used approach is air bending, where the punch presses the sheet into a die but does not make full contact, allowing for flexibility in creating multiple angles with the same tooling. This technique is popular in workshops across Australia because it minimises tool changes and reduces costs.

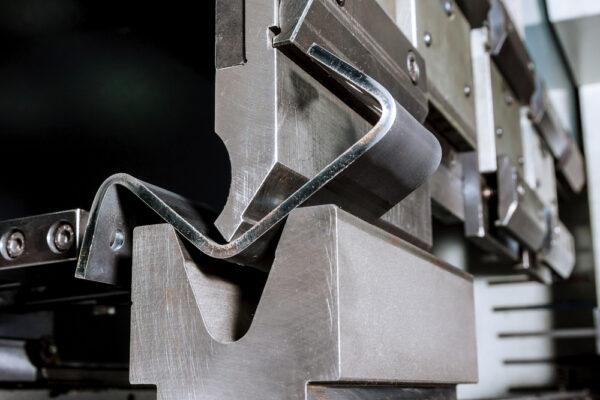

Another frequently applied method is bottoming, where the sheet is pressed firmly into the die. This produces more accurate angles than air bending but requires precise tooling and a greater understanding of the metal’s behaviour. Coining, a more forceful method, compresses the sheet to achieve exact angles with minimal spring-back. Though highly accurate, it demands greater energy input and can wear machinery faster if not maintained properly.

For complex shapes, roll bending is often used, particularly for producing large radii or cylindrical forms. In contrast, wipe bending is ideal for creating flanges or edges, commonly used in enclosures, brackets, and frames.

Each of these bending techniques has its own strengths and limitations, and fabricators must consider material properties, machine capacity, and the desired final geometry.

Role of Technology in Modern Bending

Advancements in technology have transformed how workshops approach sheet metal bending, making the process more precise, efficient, and adaptable. In the past, bending relied heavily on operator skill and manual control, but today’s machinery integrates sophisticated systems that automate much of the process. This shift has not only improved accuracy but also reduced material wastage and production time.

Modern CNC press brakes are a prime example of how technology supports metal fabrication. These machines use computer numerical control to guide every movement of the punch and die, ensuring consistent results across high-volume runs. With programmable settings, fabricators can quickly adjust angles, tooling, and sequences, making it possible to handle a wide variety of materials and thicknesses.

Another innovation is the use of simulation software, which allows operators to model a bend before it is performed. This predictive capability minimises errors, reduces trial-and-error adjustments, and ensures the final product meets design specifications. Integrated sensors and real-time monitoring also play a role by detecting deviations during the process and making immediate corrections.

For Australian manufacturers competing in industries such as aerospace, construction, and renewable energy, adopting advanced bending technology means achieving tighter tolerances, faster turnaround times, and greater adaptability to client demands. The integration of automation and digital control ensures that even complex geometries can be produced reliably, setting a new benchmark for precision in modern sheet metal fabrication.

Material Considerations in Bending

The choice of material plays a decisive role in the success of sheet metal bending, as each metal responds differently to applied stress and tooling pressure. Factors such as ductility, tensile strength, and thickness must be considered to avoid defects like cracking, warping, or excessive spring-back.

For instance, aluminium is widely used because it is lightweight and malleable, making it easier to form. However, it is prone to spring-back, which requires precise calculation of bend allowances. Steel, on the other hand, offers superior strength but demands higher tonnage during bending operations. Stainless steel is particularly challenging due to its resistance to deformation, while copper and brass are more forgiving and suitable for intricate shapes.

The thickness of the sheet also determines which technique and tooling are most appropriate. Thicker materials often require more robust machinery and larger bend radii to prevent material failure. Surface treatments, such as galvanising or coating, can further impact bending behaviour by altering friction levels and surface hardness.

Tools and Equipment Used in Bending

The success of any sheet metal bending project relies heavily on the tools and equipment selected for the job. Precision and efficiency are achieved when the right machinery, dies, and punches are paired with the correct technique and material. In modern workshops, press brakes are the most commonly used machines, providing controlled force to shape metal sheets into accurate angles and curves. These machines range from manual to CNC-operated systems, with automated options delivering superior accuracy and repeatability.

Tooling is equally critical in achieving consistent results. The punch, which applies downward force, and the die, which supports and shapes the sheet, come in various profiles designed for specific bends. V-dies, U-dies, and specialised radius tools all serve unique functions depending on the desired geometry. Choosing the right die width in relation to the sheet thickness ensures clean bends and reduces the risk of cracking or excessive wear.

Additional equipment, such as back gauges and clamping systems, enhances accuracy by positioning the sheet consistently throughout production. In Australian workshops, investment in high-quality sheet metal machinery and tooling not only extends the lifespan of equipment but also boosts productivity, enabling fabricators to handle complex projects with confidence and precision.

Common Challenges and How to Overcome Them

Despite advancements in machinery and tooling, sheet metal bending still presents challenges that fabricators must manage to ensure quality outcomes. One of the most frequent issues is spring-back, where the metal partially returns to its original shape after bending. This can be addressed by adjusting bend allowances or using methods such as bottoming or coining to lock the angle more precisely.

Another challenge is material cracking, particularly in harder metals or when the bend radius is too tight. Selecting appropriate tooling, ensuring correct grain direction, and choosing materials with higher ductility can help reduce the risk of fractures.

Misalignment and inconsistent bends are also common in busy workshops. These problems are often solved through accurate calibration of sheet metal machinery and the use of back gauges or digital controls. By proactively addressing these challenges, Australian fabricators can maintain high standards of precision while reducing costly rework and material wastage.

Applications of Sheet Metal Bending in Industry

Sheet metal bending plays a vital role in a wide range of industries across Australia, providing the backbone for products that demand durability, precision, and efficiency. In the construction sector, bent components are used for roofing, cladding, framing, and ductwork, where accurate shaping ensures both structural integrity and visual appeal.

In the automotive industry, bending techniques are essential for creating chassis parts, brackets, and panels that must meet strict safety and performance standards. Similarly, in aerospace and defence, precision bending supports the manufacture of lightweight yet strong components that can withstand extreme conditions.

Electronics and appliance manufacturers also rely on bending processes for enclosures, casings, and brackets, where exact tolerances are critical for assembly. By combining the right sheet metal machinery with advanced bending methods, Australian workshops are able to serve diverse markets, delivering components that are both functional and cost-effective.

Do You Need Sheet Metal Machinery in Melbourne?

Look no further than ACRA Machinery for your sheet metal needs. Backed by 42 years of industry experience, we are ready to help with sheet metal machinery sales, repair and maintenance.

Get in touch with us by calling 03 9794 6675 or fill out our online contact form and we will get back to you.

FAQ: Sheet Metal Bending Techniques

What are the most common sheet metal bending techniques?

The most widely used techniques include air bending, bottoming, and coining. Advanced methods like roll bending, wipe bending, and U-bending are also common for producing curves, channels, and complex shapes.

How can I reduce spring-back in sheet metal bending?

Spring-back can be minimised by selecting the right tooling, adjusting bend allowances, and using techniques such as bottoming or coining. CNC-controlled machinery also improves precision and consistency.

Which industries rely most on sheet metal bending in Australia?

Industries such as automotive, aerospace, construction, architecture, and electronics depend heavily on bending processes to produce precise, durable components.

What tools are essential for effective sheet metal bending?

Press brakes, punches, dies, back gauges, and clamping systems are fundamental. High-quality sheet metal machinery ensures consistent bends and reduces material waste.

Is automation necessary for modern bending operations?

While manual bending is still used, automated CNC press brakes and robotic systems offer superior accuracy, repeatability, and efficiency, especially for high-volume or complex projects in Australian workshops.